Proximity Switches description

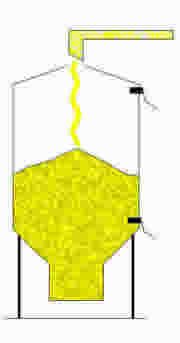

Proximity switches open or close an electrical circuit when they make contact with or come within a certain distance of an object. An example of this could be a hopper - When the contents have dropped to a certain level, the proximity switch triggers the equipment to start filling the hopper again. When the contents fill the hopper to the top, a proximity switch will be triggered to stop filling the hopper until the contents are at an acceptable level. See picture below -

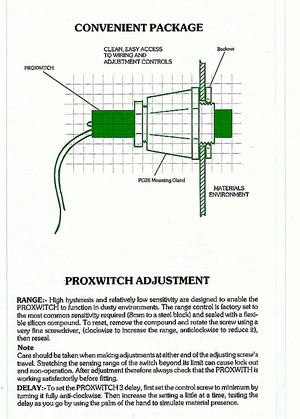

Capacitive proximity switches sense distance from objects by detecting changes around it. A radio-frequency oscillator is connected to a metal plate. When the plate nears an object, the radio frequency changes, and the frequency detector sends a signal telling the switch to open or close. Proximity switches are used in manufacturing processes, for example to measure the position of machine components. They are also used in security systems, in applications such as detecting the opening of a door, and in robotics, where they can monitor a robot or its components nearness to objects and steer it accordingly. At Proxwitch, our proximity switches are capacitive proximity switches. Applications can include the following - A basic use for example, would be to control a conveyor feeding pellets into a hopper. A suitably positioned Proxwitch proximity switch will sense when the hopper is full, and switch off the feed conveyor when the material reaches its front face. A Proxwitch 2 proximity switch will do this and switch the conveyor on again as soon as the material drops below the Proxwitch. With a Proxwitch 3 proximity switch fitted, a time delay which the user can readily set by screwdriver control, comes into action when the material leaves the proximity switch. This prevents frequent motor starts which can occur in some applications and makes the Proxwitch 3 proximity switch a complete, sophisticated control unit in its own right. By using two Proxwitch proximity switches of either type, the conveyor could be switched on when the hopper is empty, and switched off when it is full. An ideal application for the Proxwitch 3 proximity switch, would be to control the flow of grain in and out of an auger pit. When the hopper is full, the Proxwitch 3 switches the feed conveyor off. Once the time delay has allowed the pit level to fall as required, the Proxwitch 3 proximity switch will switch back, restart the feed conveyor and allow the pit to fill once again. Click here to contact us for more info or to order our proximity switches |

© 2009 - Proxwitch proximity switches, M.J Palmer & Co, Fareham, Hampshire, PO16 0TZ, UK.- All rights reserved.

Proximity switches